Complete Turn-Key Solutions

Taking your project from concept to completion

01

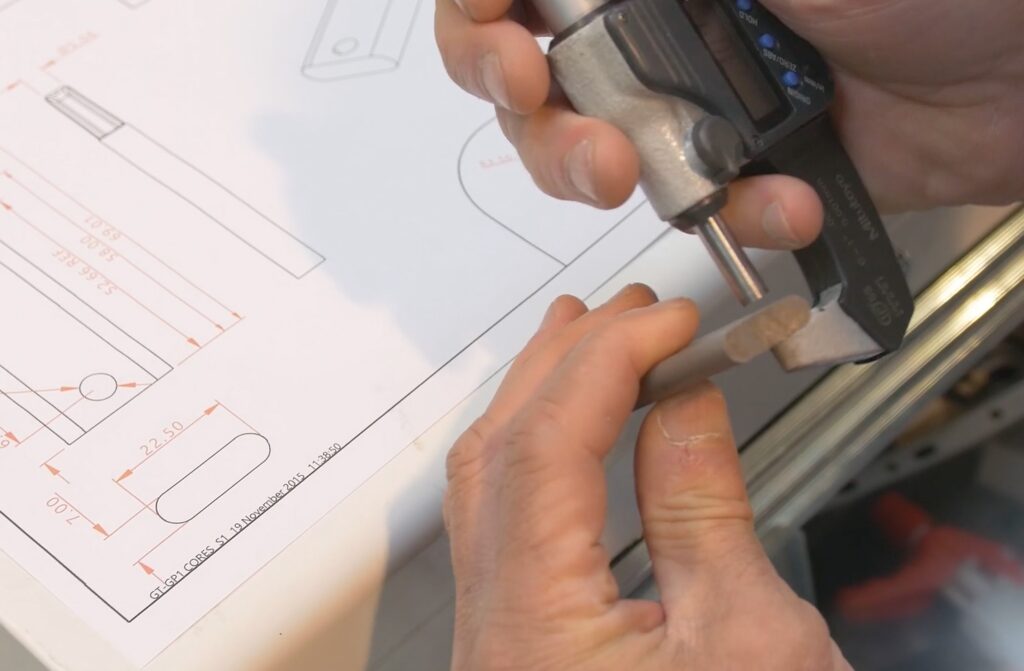

We understand your challenge

Quality and delivery are at the forefront of our minds at each stage of the project process.

02

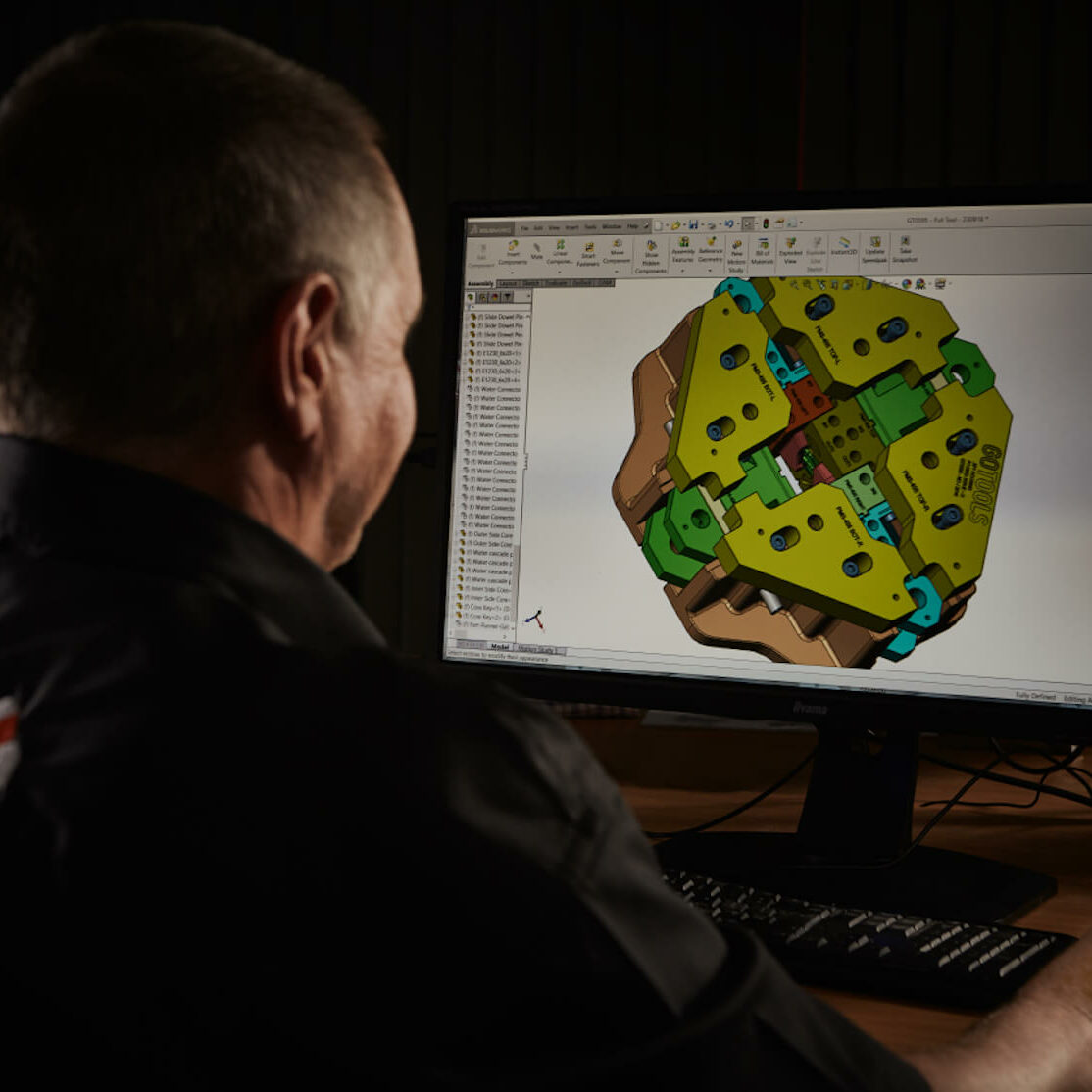

we design your bespoke tool

Our design team will ensure tooling that will outperform and last for years.

03

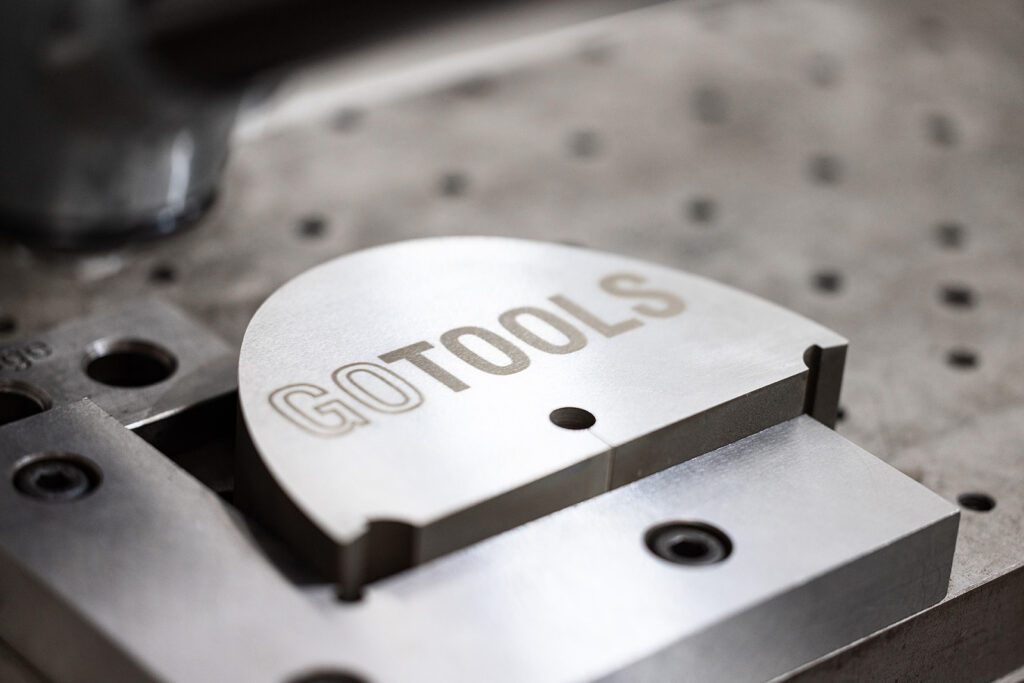

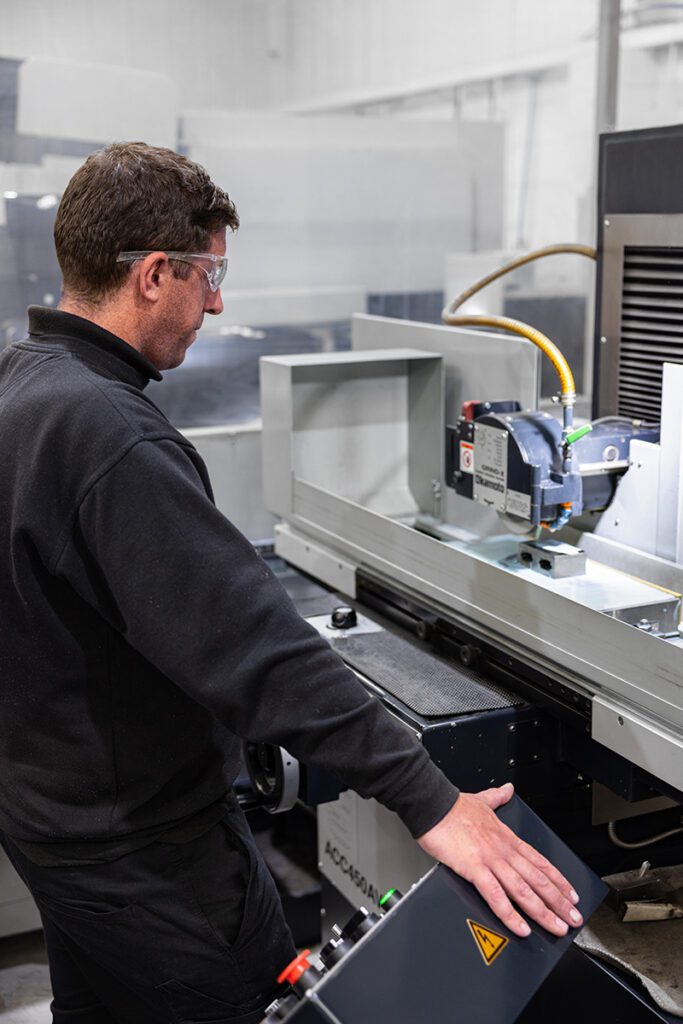

We expertly manufacture

We manufacture tooling to the highest standard while working to your deadlines using the latest innovative technology.

04

We transform your idea into reality

Once you have a tool from GoTools you will realise the benefits, giving you reliable tooling that will outperform your expectations.